Sunday - October 09, 2011

Sunday - October 09, 2011

Steve Jobs, R.I.P.

I’m sure most of you are aware that Apple founder Steve Jobs passed away October 5th. He was 56. Scary. I’m 51. All of my computers, except the first one, have been Macs. I also now have an iPad, and several flavors of iPods floating around. (no, don’t have an iPhone.) Mr. Jobs, and all of the people at Apple, make great products. And I buy them, voluntarily, because they are great products. No need for the government to dictate what computer I should own. (Oh yes, my first computer was a Commodore 64. I couldn’t afford an Apple 2e. That Commodore lasted me over a decade.)

Here is Steve Jobs’ 2005 Stanford Commencement Address. I found it interesting in that he attributes part of the success of the Mac to the fact that he dropped out of college. Sort of. Let him tell the story.

Posted by Christopher

Filed Under: • Computers and Cyberspace • High Tech • Neat Inventions •

• Comments (3)

Wednesday - April 20, 2011

Wednesday - April 20, 2011

How to make your electric company fall in love

It’s easy! Just set one of these up in your backyard, and fire it off every minute or two. Hey, I didn’t say the FAA and the fire department was gonna love you, just the electric company.

h/t to Rich K

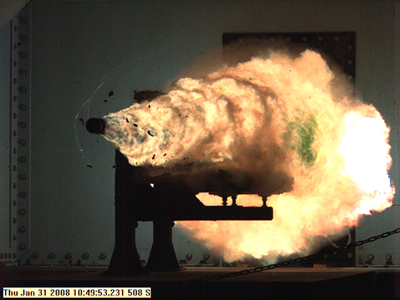

A little fun video from our pals at General Atomics. I say “our pals” because anyone who can launch a couple of kilos of metal at 6700fps is someone I want to have on my side.

Railgun launches are nothing new. What makes this one new is that they finally got around to actually using an aerodynamic projectile, wrapped up in a discarding sabot

Rather looks like a “personal size” V2 doesn’t it? And to think that the Germans figured out that shape 68 years ago.

Anyway, these guys fired off the projectile, and it shot through a steel plate a hundred yards away, and then flew another 7km before hitting the ground. And that shot was done with no elevation, so it was a horizontal trajectory. Angle the gun up and I bet you could shoot their little dart 200 miles or more.

The kinetic energy of such a projectile is up in the megajoule range, several million pound/feet worth. Surprisingly, railguns - which run on electricity - don’t really use all that much total energy. Each shot eats up about the same amount of power it would take to bake a ham in an electric oven. But while it takes a couple hours to do your ham, the railgun uses that much power in a bit less than half a millisecond.

So if it’s all-electric, why is there such a huge plume of fire coming out of the gun? It only looks like fire. It’s actually plasma interacting with the atmosphere. Which I guess does make it actual fire. Duh. But the plasma is there because a) such an awesome wallop of electricity ablates a large chunk of the sabot, and b) the projectile probably catches on fire just from the speed it’s going. It certainly is moving fast enough to c) instantly ionize the air in it’s path, and I’m pretty sure that more plasma is the result of that.

vidcap from a railgun launch from 2008.

Posted by Drew458

Filed Under: • Amazing Science and Discoveries • High Tech • Military •

• Comments (3)

Monday - March 28, 2011

Monday - March 28, 2011

Monday Digital butt dragging

Darned if I know why, but my internet is really pokey this morning. I can’t even get to my BMEWS email because the connection is so slow that it keeps timing out.

How slow is it? When things get really bad I stop by one of those speed test pages. The first test gave me 14.5 MB/s. That was to a server less than 40 miles from here. When I connected to the other end of the state, somewhere “down the shore” as we say in NJ (the rest of the planet goes “to the beach”, but not us. And we pay for beach access too, unlike anyone else on the planet), and got 5.5 MB/s. That’s mighty slow for a broadband service that says it gives me 22 MB/s. That’s the old “rated” vs. “actual” thing we’ve all been dealing with since the days of the 1200 Baud modem and the AT command set. But to be fair, most of the time my ISP runs fairly close to the 22 MB/s that I’m paying for. That’s why this morning seems pokey; it’s all relative.

So I was checking out the rest of the speed test page, and they have national and international rankings. Turns out that NJ is actually near the top nationally but the country as a whole lags far behind most of the rest of the world. OK, we’re only slightly behind the UK (10.82 vs 10.79), but quite far behind the EU broadband average of 12.16. I’d make a crack about turtles with a copper wire duct taped to their shells, but we beat the heck of out Africa, which plods along around 1.5. Most of the Far East and quite a number of countries in Europe have actual tested speeds much higher than the USA. Duh, because they are all fairly small countries with large populations with money. They don’t have the wide open empty spaces like we do.

Who provides the fastest internet? According to the speed test page, it’s a German ISP called Kabel Deutschland. Taken as a whole nation, Germany “plods” along at 18.14 MB/s, hardly more than half the average speed of South Korea’s 33.64 MB/s. But when you look at individual cities, Hamburg tops them all, beating out Seoul by two ticks with a 33.49 MB/s. Wow, that’s fast. And it’s only going to get faster. Much faster. Kabel Deutschland is the ISP there, and they have two regular and two high performance internet packages to choose from bundled with telephone service:

Telefon-Flatrate + 32 MBit/s für nur 19,90 € / 1 Monat, 29,90 €/Mon.

Telefon-Flatrate + 100 MBit/s für nur 19,90 € / 1 Monat, 39,90 €/Mon.

Sehr Gut!

Wow. 100 MB/s. That’s really fast. Not sure really what I’d do with speed like that, though KD is using it to push their own On Demand style movie service. Smart move. “If you build it, they will come.” You betcha.

What’s the cost? Well, 39,90 € is $56.20. That seems a bit steep for me. 29,90 € is $42.11 for the slower service that’s almost 50% faster than mine. Considering we pay about $109/mon. ( for bundled cable, 22 MB/s internet, unlimited telephone, no HD, no free DVR, no premium channels, all taxes and fees included), that’s a pretty good deal.

What does cable TV cost in Germany? I can’t quite figure out how the bundling works, but they do have a all in one package for sale. They give you a free ("gratis zur Nutzung!") 320 GB HD DVR with a 4 channel tuner built in, 100 regular channels, 3 HD channels, and 35 HD Premium channels including Fox and “Lust Pur” (this is Germany after all. Love the icon for that network). My German is poor, but it looks to me like they also include a Smartcard so you can shop and gamble right from home on your TV set. All this for 20,90 €/Mon with the 1st month free? $29.44??? Nah, I must be reading it wrong. That can’t be the whole 3 piece package, that has to be just the TV when you already have the 100 MB internet. Still though, even if the TV and the ISP/telephone were billed separately, the total is only 60,80 €/Mon ($85.64), which is still a really good deal even if they tack on extra fees and taxes.

Looks like American cable has a bit of catching up to do.

minimalism with a maximum message

Best logo evah!!

Gak. It took me 2 minutes to upload that dinky little icon file. Fuggedabowdit, I’m getting off the ‘net until things improve.

Posted by Drew458

Filed Under: • High Tech •

• Comments (2)

Thursday - March 24, 2011

Thursday - March 24, 2011

cryptic headlines

I’m on all sorts of news mailing lists here at BMEWS, to try to stay on top of the many things going on around us. Sometimes I get mail with a subject line that makes almost no sense. This one is an example. I read it and said “What on earth? Or maybe not on earth at all?” It sounds like some kind of futuristic genetic modeling attempt by NASA to populate one of the Jovian moons, right? Like the ones that are all water, with just ice at the surface? How far has this cloning and genetic stuff progressed when I wasn’t looking?

Wrong. Nope, that’s not it at all. This is one of those technology posts, and there are no pictures of pretty girls in it anywhere. So only peak below the fold if you’re interested. I’m interested, because, hey, how often do you ever hear about mermaid pods? What the heck are mermaid pods anyway?

Posted by Drew458

Filed Under: • High Tech • planes, trains, tanks, ships, machines, automobiles •

• Comments (3)

Saturday - February 12, 2011

Saturday - February 12, 2011

Big Brother, Now With Less CFCs

October 2010: In the Netherlands’ port city of Rotterdam, crime is way down, thanks to ... a little scientific innovation. Hoping to reel in the number of robberies, police began dishing out DNA spray to beleaguered restaurants and jewelry stores. The spray, which emits a mist laced with synthetic DNA markers unique to the business’s location when activated by employees, both marks the would-be robber and alerts police that a crime is occurring. The intention is to intimidate crooks, say police.

A sign on the front door of one previously burgled McDonald’s reads: “You Steal, You’re Marked.” Police, who note they haven’t yet made an arrest by using the mist, say such tactics are working, and report a significant decline in crime rates.

The mist, which is now being used in nine countries and coming to the U.S. soon, shows up under ultraviolent light and contains a DNA code that police stations scan for when they bring in criminals. The unique code irrefutably links criminals to the scene of the crime.

“The word DNA spreads fear into even the most hardened criminals,” said Jason Brown, business director of Selectamark, the company that created SelectaDNA Spray.

...

The mist is so fine, it’s unlikely a robber would know he’s been hit. It sinks into the target’s skin and hair where it sits for weeks.“You can take a shower three times a day, but the DNA stays on,” said Jean-Paul Fafie, the manager at one of several McDonald’s restaurants in Rotterdam, the Netherlands, that had the spray system installed.

The spray, which was developed in 2008, is being used in a series of European countries from Belgium to Hungary. The Bank of New Zealand has just invested in the product and will have all of its branches installed with the spray by next month, Knight said.

Multiple SelectaDNA Spray heads can be fitted at the entry points of premises and on activation emit a burst of SelectaDNA solution onto the offenders. The solution contains a UV tracer and a unique DNA code, linking them irrefutably to the crime scene. The DNA Spray can be armed by a panic button and/or linked to an existing intruder alarm system. As the DNA fear-factor amongst criminals is high, it is likely that sprayed intruders will flee the crime scene before stealing any goods.

Comments one Nederlander who just had these things installed in his neighborhood:

Personally, I’m glad criminals are so stupid, because they’ve never heard of UV ink solvent or protective clothing to wear under their own. God forbid that they actually go out and get themselves a black light to check.

Another issue that bugs me ... for street crimes, if somebody is watching the crime happen through the Big Brother network of spy cams, why not just call the cops instead, since the people who are watching usually ARE the cops? If you have to push the button to make the spray go off, you could set the law on them just as easily.

From a merchant’s perspective, I’d want to know “How much for just the signs then?”

Posted by Drew458

Filed Under: • Crime • High Tech •

• Comments (0)

Saturday - January 08, 2011

Saturday - January 08, 2011

Strike Two

The first unit died after 5 days. It went back. The replacement unit showed up this afternoon. Somehow I was sent one from the service tech. It arrived with the faceplate sheared off and half the buttons missing, even though the double box packaging was perfect. I’m not even going to plug it in. In went in the box broken, so it’s going back in the box broken.

There will be a rather emphatic phone call to customer service tomorrow. I wrote a red-hot letter, which I read out loud, then threw away. That’s usually the best approach in these circumstances.

I don’t know the build date for this one, but the serial number is double that of the first one. And the remote is way fancier, and the manual for the remote is dated December 2009. So maybe the first one had been sitting around the shop for years? Maybe because they knew it didn’t work???

I am starting to run out of patience.

Posted by Drew458

Filed Under: • High Tech • Music •

• Comments (4)

K-Cup Koffee?

I likes me my coffee. My usual brand is the Caribe blend, a latino style espresso that comes in a 10oz brick. Cheapest coffee on the market, but makes a nice robust, low acid cuppa when made at regular strength. I don’t make it as espresso, merely as good strong coffee. It doesn’t seem to have much longevity in the pot - it goes stale quickly - so I make up just enough for 2 mugs for me and 1 cup for her. So I don’t care too much about longevity either - those 2 mugs are gone in half an hour.

My wife’s office has one of those fancy Keurig coffee machines that take the little “k-cup” cartridge “pods” of pre-packaged coffee portions, so it makes every cup fresh and exactly the same. They had it out in the waiting room for the patients. She’s always going on about how wonderful it is, mainly because it only takes a minute to brew a mug’s worth, and because the little k-cups come in so darn many varieties, and she loves all the fancy-nancy flavors.

So anyway, the folks at the office used their machine daily for 2 years and then it stopped working. Turns out they never once cleaned out the machine, or ran some white vinegar through it to de-scale the pot. She brings it home Friday and wonders if I can do anything with it. Um, thanks. I’ll look at it Saturday.

So today I went and got a gallon of cheap white vinegar and filled up the tank, wiped down the little gizmo that holds the k-cups in place, cleaned out the needles, and went over the whole pot with some detergent in a sponge, followed by a rinse and then a wipe down with rubbing alcohol. Used a toothpick and a Q-tips for all the nooks and crannies. That got every last bit of dirt, grease, and old coffee grime off the pot. I then stood there in front of the machine and ran a gallon of vinegar through this machine one mug at a time ... and then, WTH, ran it through my old Mr. Coffee pot as well, with a filter to catch any bits. 13 mugs worth. Put the hot vinegar outside for 10 minutes to cool, then ran it through both machines again. The Keurig’s instructions say to leave the machine in standby mode for 4 hours, then to run several tanks of fresh water through it. That gives the vinegar plenty of time to clean out the inner water holding tank, and then get everything rinsed clean.

While I was waiting, I looked up any issues with the machine online, and found out 2 ways to reboot the unit when things go wrong: one complex method that is the coffeepot version of the old “Ctrl-Alt_Del”, the other method tells you where to smack the machine to make it go. I like that one the best!

So I do all that cleaning and rinsing, and now the pot works perfectly, no whacking or rebooting necessary. Here you are honey, take it back to work. “Oh, no, I don’t have to. They said they’re ordering a new pot anyway since this one was broken, so if you could make this work we could keep it.”

![]() Great! Hey, if they can afford to throw away money that easily, maybe they can afford to give you a raise!

Great! Hey, if they can afford to throw away money that easily, maybe they can afford to give you a raise! ![]()

So now I have a fancy-do $150 coffee pot, that works just as well as my $15 coffee pot.

These things are kind of popular, so I’m sure several of my readers have them. Can you tell me if they make economic sense? Or if the taste is so superior that the extra cost is justified? Or they even save time? I’m not going to leave this thing in 1500 watt power eating “standby” mode all day; I’ll turn it on in the AM, give it 3 minutes to warm up, crank out 3 or 4 cups of coffee, then turn it off. That’s about how long it takes my regular pot to brew things up.

I’m going through about 8 “8-cup” pots (ie 4 mugs worth per pot) of coffee a week, which uses no more than 1 10 ounce $1.99 brick of Caribe. I think that works out to 6.2¢ per mug. Once in a while I’ll have some of the flavored decaf the wife sometimes makes in the evening, but most of the time I avoid both decaf and flavored coffees. Are these k-cup things sold in real bulk (500) so that the price comes down?

PS: old guy rant: It sucks arabica beans that we’ve been downsized so damn many times that a “pound” of coffee now only weighs 10 or 11 ounces. And a “cup” is now somewhere between 4 and 6 ounces. GTFOH. No. NO! Sorry, a pound is 16 ounces, and it fits in exactly the same size can as the 11 ounces they sell today. And a cup is 8 ounces, even though almost everyone in America drinks coffee by the mugful, and that’s a 12 ounce pour. Sure, we’re using more coffee than ever before, and drinking better coffee than ever before: today’s Mr. Coffee style drip pots use more grinds per cup than the old school percolators. They also make a better tasting cup because the water isn’t boiled through the grinds endlessly. But there is no coffee shortage. We’re just getting screwed over by the industry, and they’re trying to hide that by downsizing the packaging and by downsizing the serving size. That way we “won’t” notice that the stuff that used to cost 85¢ per pound now costs $8 per pound.

PPS - one thing that I do like about this Keurig machine is that it has adjustable water temperature. You can set it for a maximum of 192°F, and actually get a hot cup of coffee. Neither McDonald’s nor Mr. Coffee will do that for you these days.

Posted by Drew458

Filed Under: • Fine-Dining • High Tech •

• Comments (9)

Thursday - November 04, 2010

Thursday - November 04, 2010

I wonder how much the toner costs?

It didn’t jam the printer but there’s no guarantee it won’t get stuck in traffic.

Two companies in the US have partnered to design and create Urbee - the car built entirely by a 3D printer.

Urbee was made using additive manufacturing processes, which prints layer upon layer of material to create a product.

Many manufacturers, including aeroplane giant Boeing, print their parts, but this is the first time an entire machine prototype has been created using the 3D printing process.

Every exterior component of Urbee, including the windscreen, was made using Dimension 3D printers and Fortus 3D Production Systems by Stratasys, who teamed up with Kor Ecologic to create the energy efficient car.

Jim Kor, president and chief technology officer for Kor Ecologic, said the process eliminated tooling, machining and handwork.

The electric/petrol hybrid car is extremely fuel efficient, getting approximately 85km/L (200mpg) on the highway (100mpg city).

A standard 4WD uses about 10 times the amount of petrol to go the same distance.

The futuristic looking vehicle can be charged from a regular household power outlet - just plug it in overnight - or can draw power from renewable sources such as sunlight or wind.

This combined with the environmentally friendly production process is part of the manufacturers’ goal of Urbee being “as green as possible”.

3-D printing has been used for manufacturing before. Boeing, for example, prints some airplane parts using the process. And a company called Bespoke Innovations is using 3-D printing to manufacture prosthetic limb casings. But Urbee is entirely 3-D printed--all exterior components were produced with Dimension 3D Printers and Fortus 3D Production Systems by Stratsys.

...

“FDM lets us eliminate tooling, machining, and handwork, and it brings incredible efficiency when a design change is needed,” Jim Kor, president and chief technology officer at Kor Ecologic explained in a press release. “If you can get to a pilot run without any tooling, you have advantages.”

Posted by Drew458

Filed Under: • High Tech • planes, trains, tanks, ships, machines, automobiles •

• Comments (3)

Friday - October 29, 2010

Friday - October 29, 2010

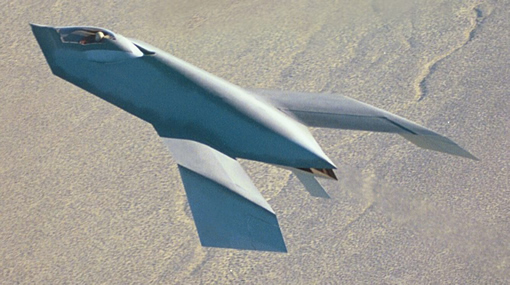

Out of the Black and Into the Blue

This is a one of a kind test aircraft made by Boeing called the Bird Of Prey. Once upon a time it was the blackest of black projects, but it was declassified and shown to the public back in 2002. It was built with as many off the shelf parts as possible to keep the project cost down $67 million. It could neither fly high nor fast, and was a handful to land. And it seemed to generate UFO reports whenever it flew. I wonder why?

From a 2002 news release: Named after a Klingon spacecraft in “Star Trek,” The Boeing Co. yesterday took the wraps off what was once one of its most classified “black” military airplane projects known as the “Bird of Prey.”

The Bird of Prey plane is 47 feet long with a distinctive 23-foot wing at the rear shaped like a “W.” The Boeing project ran from 1992 through 1999. The plane, which looks like something that should be flying—and probably once did—at the super-secret Area 51 Nevada test range, helped Boeing pioneer stealth technology and new and more-affordable ways to design and build airplanes. The classified project ran from 1992 through 1999, and Boeing said it decided to make the aircraft public because the technologies that were demonstrated have become industry standards.“With this aircraft we changed the rules on how to design and build an aircraft, and what we’ve learned is enabling us to provide our customers with affordable, high-performing products,” said Jim Albaugh, president and chief executive of Boeing’s Integrated Defense Systems.

It was developed by the McDonnell Douglas Phantom Works organization, where many black, or secret, projects for the military ended up, just as they did at the famed Lockheed Martin Skunk Works.

The Bird of Prey incorporated a variety of stealth features to minimize radar, infrared, visual and acoustic signatures. The overall shape of the low profile, tailless, blended fuselage with sharply cranked aft-set wings contributed to an extremely low radar cross-section. Flexible covers concealed gaps between fixed structures and moveable control surfaces. Designers were careful to ensure edge alignment on the canopy, landing gear doors, wings and fuselage to minimize radar backscatter. To eliminate radar reflections from the engine compressor face, the powerplant was buried deep in the fuselage and hidden behind the canopy and a curved inlet duct. The engine exhaust mitigated the airplane’s acoustic signature. A paint scheme consisting of several shades of gray reduced the visual contrast of shadows from various parts of the airplane. All of these features would contribute significantly to the survivability of an operational combat airplane.

As the team learned the lessons of each flight, the test program proceeded at a leisurely pace. Only 38 missions were flown between September 1996 and April 1999, roughly one sortie per month.

A video is here.

Funny thing though ... all the articles out there keep saying the aircraft was built to pioneer stealth technology. In 1992. Even though the F-117 and B-2 stealth aircraft had been in the field since the early 80s, which means they’ve been around since probably the early 70s. So what’s the point of “pioneering” it in the early 90s? Well, take your pick:

a) it was pioneering work for Boeing, because the other stealth planes were built by Lockheed/Martin/Marietta and Northrop Grumman. So when Boeing bought out McDonnell/Douglas, who had started the project, they actually had no stealth experience themselves, so this was a prove-we-can-do-it project ... or

b) the real purpose of the project is still deep in the black. They only tell us it was a stealth demonstrator and a low performance flying testbed. Was this an early Aurora prototype? The truth really isn’t out there; we will never know for sure.

Posted by Drew458

Filed Under: • High Tech • History • planes, trains, tanks, ships, machines, automobiles •

• Comments (2)

Wednesday - October 27, 2010

Wednesday - October 27, 2010

Going Through The Motions

Looks like we are going through our annual noise-fest about scruffy election controls. Poll workers stuffing ballot boxes!! Nevada ballots handed out with Harry Reid’s name already checked! Acorn! Feds strike down Arizona proof-of-citizenship voting law! Racism!! Diebold voting machines are rigged! Glen Beck forecasting riots and blood in the streets!!!!

There they go again. Sound and fury, signifying nothing.

Don’t get me wrong; I believe strongly that many of the election processes around the country “have their thumb on the scales” so to speak. And it is something that people should be aware of, and that needs significant citizen watchdogging. Groups like True The Vote down in Texas, and others, are doing a great job.

The problem is, aside from a few contested recounts, we won’t hear another word about this starting three days after Election Day. But I can guarantee you that when it comes time to vote next year, about a month out we’ll hear all the same crap once again. Voter fraud has become another one of the annual fear topics for the media to trot out seasonally. No different from the “experts predict this will be a terrible year for hurricanes” or the “we’re all going to die from flu this year, and the government/big pharma doesn’t have enough vaccine to go around” tales. Sound and fury. And nothing ever ever gets done.

Ok Tea Party people, I’ve got a job for you. A job that needs doing in every town, city, county, and state across the nation. A job that does not need to be done once, but needs to be done all the time. We are a fractured nation, broken along political lines. We need to close that fracture. We need to have not only a more honest government, we need people to have faith in that government. And that faith starts with people having faith in the election process. Ok, it also starts with people having faith that the candidates running for office are legally qualified to run, such things as showing public proof that they are citizens, natural born ones if necessary, or that the ones running for Mayor of Chicago have followed Chicago’s law and have actually lived day to day in Chicago for the past several years, but that’s not what I want to discuss here. I want to talk about cleaning up the voting process. I’ve done this before, so I’m equally guilty of the seasonal scare story too, but the only reason I’m here talking about it again is that no solutions seem to have been put in place.

If one of these ever-present polling companies were to take a large nationwide poll, perhaps half a million people chosen at random, and asked about their views on the voting process, I could probably guess within a few points what the results would be. You would find that 2/3 to 3/4 of the left to far left leaning folks do not believe that any monkey business is afoot. You would find that 2/3 to 7/8 of the center to right leaning folks believe that not only are the monkeys out there, but they are fed steroid laced bananas and that they all have turbochargers hooked up to their little monkey butts. You would also find that at least 80% of the leftish people say that any kind of effort to clamp down the election process is racist, while fewer than 30% of the rightish types feel that way. Heck, if you asked that question the proper way, 90% or more of the right leaners would say that a rigid election process is patriotic.

Let me posit a solution. Yes, I lean to the right. You may have noticed this once or twice in the past. So much so that sometimes I wonder how I manage to stand up straight. So hold on to your seats, because I’m going to do something radical. I am calling for an increase in government. More government workers. Shocking, I know. But the only reason I am calling for this is that the voter registration process is often left to the lowly county clerk, who has about a billion other jobs to do. And a strict and structured registration process is going to require some staffing. No, you don’t have to pay these people $185,000 a year each. But it’s a $40,000 job for a number of them, and a $65,000 job for 2 or 3 managers. And everyone who gets one of these jobs takes it with the full knowledge that their job is on the line each and every day. Screw it up and you are history.

My solution is radical because it is simple. It does not take rocket science or a Master’s degree in engineering to do. All it takes is cooperation, and the honesty to put aside the willful blindness of PC. Let me get all “post racial” and “bipartisan” like our wonderful president: skin color does not preclude you from making a bit of effort to get yourself registered to vote. Period. No discussion necessary. Physical motile ability does not preclude you either. Nor does advanced age. Nor does sexual orientation ... come on, who gives a damn what you bump uglies with when it comes to voting?

My solution does call for cooperation among the branches of government. In our post-9/11 world, that wall that Jamie Gorelick built has to come down everywhere. Blanket statements from the Social Security folks that they are not going to cooperate is a no-go. It’s cause for instant dismissal. Period. Same goes for the military and the criminal justice people. Be part of the solution, or be gone.

So, where do we begin? First up would be proof of citizenship and proof of age. We do not have a de facto National ID card in the United States. And rightfully so. But we have the next best things. We have our Social Security card, our state issued driver’s license, the IRS, the military, and our credit cards. Everything runs on plastic these days. Every one of those knows our age and our current address. And our Social Security number, because 99.987% of all citizens over the age of 18 have one. Oh, but laws say you can’t use your SSN for purposes of identification!! Really? Then why does every single form you fill out anywhere for anything have a space for your SSN? Change the law, or at least put in a caveat for voter registration. And at least one of those groups has a picture of you. So the first step is fairly easy. To register to vote, you need to show up at the clerk’s office well in advance of Election Day - 90 days or more - and prove you are eligible. They have a limited function card reader, just like the one in the grocery store, but with a better screen. Enter your numbers or swipe your plastic, and the result that comes back has your name, your current address, and you SSN. Does that match what you’ve put on the registration form? Good, you’ve just passed Step One. The clerk presses another button, which sends your SSN to the criminal justice databases. And I say databases, because there are lots of them. Hey, I’ve been through the NJ pistol permit process, so I know. And the only data that gets returned to the clerk is a green light or a red light. Green light means proceed, red light means stop.

Should convicts or felons on probation have the right to vote? That’s a side issue, and one that should be solved by state or national referendum every so many years. Personally, I feel that if you have done your time, you are back in. Still doing time, still on probation, no vote for you ... if the crime you were convicted of was serious enough to disable your voting rights. And all the crimes that do take away that right need to be gone over and looked at again with an eye on “cruel and unusual” and “excessive fines and penalties”. But that’s another side issue on this side issue. However if you are convicted of such a crime, then you have to turn in your registration card.

Assuming you get a green light, the clerk takes your picture, and creates a voter registration card for you, with your photograph and its own unique number on it. And that card expires every 7 years, so you have to go through this again and again throughout your life. Too bad. Voting is a right, but it’s a right you have to make a bit of effort to use. Tough titties. But there is no cost, no charge, no fee for getting a registration card. And every county seat or town that does registrations puts the office right on the public transportation routes. Hospitals have a staffer or two on stipend to do the task remotely for long term care patients. And for shut-ins, old folks in nursing homes, etc., the county sends some people around, on appointment by request. So if you can’t come to the office, the office will come to you. But only for those who actually, really, honestly can’t. The lazy and uppity folks who can’t be bothered to go downtown to register and who just make an appointment are hit with a $2500 fine for wasting the government’s time. My plan makes everyone make some effort, so you’re going to get a slap down if you try to play the system.

Hold onto that registration card and keep it in a safe place. Bring it with you when you vote. Just like the “Got your Show Me?” billboards in the alternate universe in the Fringe TV show, public reminders are run several weeks before the elections. Show up to vote with your card AND some sort of current bill or government letter addressed to you as proof of current address. The poll worker checks your face against your card and swipes it. Got the green light? They match the retrieved address against the piece of mail you brought with you. If they match, then go ahead and vote. Got the red light? The clerk will enter your information manually. Still red? No vote for you. Period. It’s your duty to make sure your card works ahead of time, especially since there are only two reasons the red light would come on: false information or recent conviction of a crime that takes that right away. Oh, I forgot my card, I lost my card!!! Fine. See that line over there? Get on it. And that clerk will enter your information manually, and she won’t work all that fast, but if you are legit, then the system will Ok you and you can vote. Oh no, I forgot to register. Can I do it now? Go to hell. Sod off. No, you can not register today, nor can you vote today. Not even provisionally.

People who have moved between one election and the next are responsible for getting their registration cards updated well in advance of Election Day. Those who have not updated their current address can go back to where they live and vote this one time ... and the clerk will then take and destroy (in front of witnesses) the registration card. Can’t I have an absentee ballot? No, because there are no more absentee ballots. They are a thing of the past. And to make sure that duplicate IDs are not issued, any new ID card issued shuts off any existing cards under that SSN and name.

What??? Whaddya mean, no more absentee ballots???? Just what I said. They are a thing of the past for those able to make the effort. Yes, for the hospitalized, the disabled and so forth they still exist. But those people are already on a list that lets them use this method. For everyone else, you have to make the effort to exercise your right, and get your lazy ass to the polling station. But we’ll make it easier, and from now on Election Day will be Vote Counting Day. That means the polls are actually open from 8am to 10pm every day of the week for 3 weeks beforehand. Hire a couple of people as temps at a tax free $10/hour to man the voting booth, with the caveat that if they let an improper voter vote then they go to jail for 6 months. Train them and test them, and give them support ( a cop and the town clerk ) if they have to turn anyone down. And woe be unto the person who attempts to vote, gets turned down, raises a fuss, has the support people called in, and is found ineligible to vote. 10 days in jail and a $1000 fine.

Um, I’m dead. Does my vote still count? Um, no. The coroners have to send in the data on the newly dead every single day, once positive and unassailable identification has been made. And fined if they screw up or forget. And the county clerks will process that data every day, deactivating the registration cards of the deceased. Show up to vote while “dead” and you can’t vote ... because the onus is on you to make sure your registration is in order ahead of time. No excuses, not even death.

If you have gained or lost massive amounts of weight, suffered from some horrible accident or illness that has radically changed your appearance, or undergone elective plastic surgery to the extent that the new you doesn’t look a thing like the old you ... then the onus is on you to get your registration card updated with a new photograph. And do it well ahead of time, and don’t forget to bring several forms of ID and proof of current address with you. Those folks just released from the hospital can go back there to do their voting if their release date falls between the registration cut-off date and the polls opening date. Once the hospital’s stipended polling worker verifies that you were a recent patient they will take your vote, as long as you get that good old green light.

And that’s about all there is to it. The military would set up it’s own system, the troops would vote ahead of time, and those votes would be sent in early. Early enough so that any bumps or glitches could be hammered out before Vote Counting Day. Ex-pats living abroad would have to show up at the embassy and vote there. Same process, same visual and electronic verification, same penalties for abusing the system, and the same vote ahead of time schedule that the military uses.

I think I’ve covered all the bases. Voting is a right that we should cherish, but the exercise of that right should not be whimsical. Put some steel in the backbone of the system and sharpen its edges to guard against abuse. Putting a system like I have outlined into place will cost something, but it won’t cost billions and zillions. But it will stop the dead and the false from voting. And that’s a big step. Please feel free to fill in any gaps I’ve missed, or to shoot my plan full of holes if you don’t think it will work. But if you do, I’d really like to read about your alternate plan. Because we need a plan, and if mine won’t do the job then maybe yours will. So pony up.

What about illegals who have fraudulent or stolen SSNs? Once again, this is where the branches of government have to digitally cooperate with each other. Digitally, because this kind of thing is a database to database communication with little or no human input. Social Security knows what numbers are valid, and what names those numbers were issued to. The credit card companies, the banks, and the utility companies - the sources of those letters that prove current address - know where you live. So showing up to vote with a falsely obtained registration card, or even trying to obtain a registration card under false pretenses, sets off an alarm. And alerts the cops and ICE. And earns the registration clerk a $100 bonus for bagging an illegal or a cheater. But that’s another side issue.

So what do we do about them that scream raaaaacism when anyone tries to True The Vote? Throw it right back at them: they are guilty of the prejudice of lowered expectations. They are in support of fraud. Don’t question their patriotism, deny it entirely. We The People are all equal in this. Belonging to any kind of group - ethnic, religious, sexual orientation, whatever - has no bearing at all. And it’s high time we took that stance, took up the fight, and won this little pissing contest once and for all. The first step to recovering national faith in our leaders is making sure that the electing of those leaders is done only by the properly qualified citizens. The next step is making sure that the system used to do that electing is honest and bulletproof. The next step is making sure that the people vying to become elected leaders are qualified to do so. The step after that, once they’ve been elected, is holding their feet to the fire every single day to make sure they do what is right. And that’s what we have to do to get our country back.

http://townhall.com/columnists/MichelleMalkin/2010/10/27/the_lefts_voter_fraud_whitewash

http://www.slate.com/id/2272405/

http://www.foxnews.com/politics/2010/10/26/court-strikes-ariz-law-requiring-voters-prove-citizens/

Posted by Drew458

Filed Under: • Crime • Government • High Tech • Politics •

• Comments (1)

Saturday - July 24, 2010

Saturday - July 24, 2010

Newest Ship In The Army

Just over six months after the official opening of Austal’s new Module Manufacturing Facility (MMF) in November 2009, Austal USA hosted a keel-laying ceremony at its shipyard in Mobile, Alabama on July 22, to signify the erection of the first modules on the U.S. Department of Defense’s next generation multi-use platform, the Joint High Speed Vessel (JHSV). This is part of a 10-ship program potentially worth over $1.6b.

Keel Laying is the formal recognition of the start of the ship’s module erection process. In earlier times it was the “laying down” of the central or main timber making up the backbone of a vessel. Today, fabrication of the ship modules begins months before the units are actually joined. However, the keel laying symbolically recognizes the joining of modular components and the ceremonial beginning of a ship.

Spearhead (JHSV 1) will be a US Army vessel (USAV) and its name represents a major feature of the Regimental Insignia of the Transportation Corps. The insignia is a gold color metal and enamel device consisting of a ship’s steering wheel bearing a shield charged with a winged vehicle wheel on a rail, all gold, centered upon a brick red spearhead point up, all standing upon a curving gold scroll spanning the lower tips of the spearhead and inscribed, “Spearhead of Logistics,” in blue letters.

The ceremony signified the erection of the modular components that will form part of a 338 ft aluminum catamaran capable of transporting troops and their equipment, supporting humanitarian relief efforts, operating in shallow waters, and reaching speeds in excess of 35 knots fully loaded. This is the first of a class of 10 vessels to be operated by both the US Army and Navy.

For some old timers who might be wondering if the Army having it’s own ships isn’t some form of wackiness, what I found out about this class of vessels is anything but. For starters, these JSHV ships are fairly inexpensive at under $200 million each, ready to sail. The ships themselves are only slightly modified, armed versions of an existing commercial design, the shallow draft trimaran ferry built by Incat Tasmania Pty Ltd., of Hobart, Australia, now partnered with Bollinger Shipyards of Mobile Alabama and doing business as Austal.

The ships are 338 feet long, and made primarily from aluminum. They are wide beam, shallow draft, light weight, and very stable. They can hit 35 knots or faster, and they use far less fuel than standard ships of their length or capacity. The Navy has been testing a few of them for most of a decade now, and everything seems to work well. The design is pretty odd, and highly modern.

These “little” ships will serve mainly as “floating pickup trucks” moving goods and people. I do not know what their role will be regarding the LCS (littoral combat ship) paradigm. The Spearhead and her sister ships can carry more than 300 troops quickly to shore and back again. This is the same ship design that Hawaii used for an inter-island high speed large superferry, until the enviro-wienies killed it. Those ferries could move 866 passengers and 282 subcompact cars at one go, and used jet propulsion instead of propellers to minimize risk to sea life. But that wasn’t good enough for the greenies!

All in all, it looks like this project was put together with a miraculous amount of common sense. Off the shelf ship that uses a radical but efficient and proven design. Cost effective from one end to the other. See what that kind of ship can do - the earlier ships tested by the Navy were used for logistics support in Iraq, to ferry aid to victims of the Indonesian Tsunami and victims of hurricane Katrina - then grow a role for the military around their capabilities. That’s the exact opposite of the I Have A Hammer approach, where they try to make everything look like a nail.

The JHSV (Joint High Speed Vessel) is a new generation, multi-use platform capable of transporting troops and their equipment, supporting humanitarian relief efforts, the ability to operate in shallow waters, and can reach speed in access of 35 knots fully loaded. The project brings together United States Navy, Army, Marines, and Special Operations Command to pursue a multi-use platform.

Originally built as a car ferry, the Swift [one of the earlier test ships] is a wave-piercing catamaran, a two-hulled, multi-decked craft with the length of a football field. She has a mission bay with 15,500 square feet of vehicle and module space. Her crane can launch and recover small boats. Her vehicle ramp is sturdy enough to accommodate M1A1Abrams tanks. A 4,000-square-foot flight deck has an adjacent hangar for two MH-60S Knighthawk helicopters. She can carry up to up to 250 combat-equipped Marines resting in airliner-style seats and up to 605 tons of cargo.

Propelled by four sets of Caterpillar 3618 marine diesel engines, gas turbines and water jets, she can cruise at a top speed in excess of 45 knots.

Yet the Swift’s aluminum hull draws only 11.15 feet of water. This allows her to operate in the shallow coastal waters of the Gulf of Mexico—or similar regions anywhere in the world. In the two years since the lease began, the vessel has provided transit support during the invasion of Iraq, participated in exercises off the coasts of West Africa, Honduras and Norway and provided tsunami disaster relief in the Indian Ocean.

“The Swift’s high speed makes it extraordinarily responsive, compared to other vessels,” Sodol said. “The higher payload requires fewer trips than a smaller high-speed craft, and the shallow draft enables it to enter ports and use small piers that are inaccessible to deep-draft ships.”

The Army and the Navy are alternating ownership of these ships. The first one built, Fortitude, and this one, Spearhead, are Army ships. #2 and #4, Vigilant and Fall River, will be Navy owned. So maybe it’s wrong for me to call this vessel USS? Maybe USAS instead? Naming conventions are out the window at this point, though the Fall River will be USNS.

Note to dedicated ship spotters: This is not the TSV-1X Spearhead, even though that ship is nearly identical to this one. TSV-1X was a test ship (hence the X) and this one will be a line ship. But the Army so loves the name it will get used on this one as well.

I can’t say how this new class of smaller, chunkier ships will fare in the long run, but one oxymoronic benefit they have is that they are not visually intimidating. Seriously. Maybe we all grew up understanding that the Navy was a floating steel manifestation of Force Projection, but that might be a bit unsettling for other countries when the Navy stops by for a social call.

A now-familiar gray catamaran pulled into the city of Port Antonio, Jamaica, on Jan. 4, carrying a team of sailors and Marines set to deliver a lesson in high demand among all the seafaring nations in Caribbean — how to fix small boats.

Boat repair, port security and basic law enforcement are part of the core curriculum available from the trainers aboard the high-speed vessel Swift, now three nations deep into a seven-nation tour of Central and South America as the United States’ floating embassy. Dubbed the “southern partnership station,” the Swift is becoming a regular visitor to many ports in the 4th Fleet area of operations, which is exactly what the Navy wants.

“This puts the U.S. military in good standing down here with these countries,” said Cmdr. Chris Barnes, the Swift’s mission commander, who spoke to Navy Times from Jamaica.

“In the three countries where we’ve been so far, we’ve been very, very well received. They appreciate the training, and we’re learning stuff from them, as well.”

Hearts and minds ... the theme that just won’t quit. All well and good in peacetime, but the real reason behind these ships is that they can take a quarter thousand soldiers in comfort and all their gear - the equivalent to 20 C-130 cargoes - and get them nearly up on the beach anywhere, and then offload the whole thing in under 15 minutes. Neat rah-rah video here.

Posted by Drew458

Filed Under: • High Tech • Military •

• Comments (7)

Thursday - May 27, 2010

Thursday - May 27, 2010

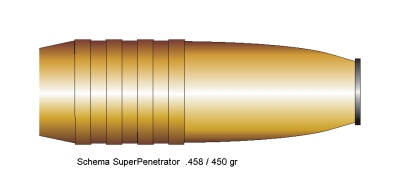

High Tech Hunting Bullet

That picture may not look like much to most folks, but there is an impressive amount of science behind this bullet. What you are looking at is the dawn of the 7th generation of consumer firearms projectiles. Not only is this bullet “green”, it can also shoot through water for a considerable distance, which no other bullet has ever been able to do. When used against dangerous game - very large animals that may be actively trying to kill you while you are actively trying to kill them - it is designed to out-penetrate every other kind of bullet on the market and to create a larger wound channel than any other “solid”. It’s the best of all worlds in it’s own little specialized niche. Woodleigh is a bullet making company in Australia.

This is an elephantine post about an elephant bullet. If you don’t want the technology lecture and the history lesson on bullet design you can skip ahead to the end. Or go on to the next post, which may have titties. Or not.

In the beginning, back before John Moses Browning (PBUH) created the world as we know it, there was the lead ball. You poured a charge of black powder down the long thin barrel of your musket, wrapped a bit of greased cloth around the big lead ball, and stuffed it down the tube. When fired, it accelerated to about 900 feet per second and generally went forward. If the distance was very short, say less than 75 yards, you would hit what you were aiming at, mostly, and the big soft lead ball would put a large hole in it. Providing that what you were shooting at wasn’t really thick; unrifled muskets don’t put any spin on the ball, so the round bullet isn’t stabilized at all, and has no forces acting on it to help it burrow in in a straight line. But lead is soft, and that 3/4” diameter ball squashed itself out to 1 1/2” across on impact, and created a pretty damn big, if shallow, hole. And that was enough. Unless you were hunting bears or lions or big angry buffalo, in which case you wanted half a dozen friends along with their own muskets so they could shoot too. And then you could all run in different directions, and hope that the critter chose to chase someone else.

At some later point rifling was invented. Exactly like the threads on a screw, but with a much longer spiral, rifling imparts an axial spin to a bullet as it is fired down the barrel. This made that ball fly much straighter, which allowed those primitive boomsticks to have some degree of accuracy for the first time. The spinning also caused the ball to penetrate much further, or at least straighter. It was a big step forward. Now you only needed a couple of friends along.

Pointed bullets came next. Conical projectiles, the Minie ball. Paper patching, lubricated grooved bullets, better metallurgy, better casting, harder alloys of lead and tin and antimony, a bit of aerodynamics, and soon thereafter reliable weather resistant metallic cartridges, repeating rifles, smokeless gunpowder with a whole lot more energy. There was a tremendous technical leap forward in the 30 year period from 1860 to 1890. So much progress that the old raw lead bullet could not (literally) take the pressure, and would smear itself to pieces inside the barrel upon firing.

So the chunk of lead got squeezed into a copper jacket. “Gilding metal”, a soft and smooth brass alloy, soon replaced copper. A few years later it was found that the “spitzer” shape, a pointed bullet with a mathematically derived pointed ogive on the front, was highly aerodynamic. This allowed bullets to to be accurate to extraordinary ranges and to retain considerable kinetic energy all the way there. The modern rifle was born. 110 years ago.

In the interim folks have fussed and tweaked with the design of the bullet. A longer point, a shorter point. Flat base, tapered base (ie boat tail) Exposed lead tips vs. full metal jackets. Lead cores cast in place in their jackets, glued in, electrochemically bonded in, locked in place with swaged grooves. Different thicknesses and hardnesses of the metal jacket. Bronze points, plastic points, steel and tungsten rods inserted in the lead cores. All attempting to build a bullet that worked the best on a certain sized creature at a certain velocity range. And with pretty good success too; there is an amazing variety of very effective bullets on the market today, so many that it’s almost work trying to figure out which one is the best for your hunting trip. Bullets have become highly specialized.

A few decades ago solid copper and bronze bullets came on the market. This is where the “green” part comes in, tangentially. Environmentalists have been quite successful in getting lead shotgun pellets banned in many places. Lead has always been used for shot pellets and for bullets, because it is very dense, malleable, abundant, and cheap. But when you shoot at some birds with your shotgun, not all the pellets hit. Some fall to the ground or into the water, where a poor little birdie or fishy might eat them. And get lead poisoning. It’s a helluva stretch, but it is just barely conceivable. And it shows you just how much political power the anti-gun, anti-hunting brigade really has. So the shotgun ammunition world is moving away from lead shot, using steel, bismuth, or tungsten pellets instead. The bullet makers can read the writing on the wall, and now lead-free, solid copper alloy bullets are all the rage. Primers don’t even use lead styphnate (C6HN3O8Pb any more because that’s a “toxic explosive” and you mustn’t be exposed to even microscopic amounts of lead vapor. God forbid actual lead. So let’s use copper bullets. “Problem” solved.

So, while “green”, copper bullets have a whole pile of issues of their own. Copper is much less dense than lead, so a bullet of a certain size and shape will weigh a lot less. Which means that at equal velocity it will carry much less kinetic energy; it will not have as much power. Conversely, copper bullets of equal weight to their lead cored counterparts will be much longer, and may not chamber properly in the magazine or the chamber throat of the firearm. Sure, easy, seat them deeper into the case. But that takes up a lot of internal volume that the gun powder used to use. Copper is also much harder than lead, and solid copper is much less malleable than the thinly jacketed bullets we’ve been using for 100 years. This makes the engraving process - the act, upon firing, where the suddenly accelerating bullet is forced out of the cartridge case and into the barrel’s rifling lands and grooves - much more difficult, and that raises chamber pressures. Chamber pressure is what you get when you light off a charge of gun powder inside your gun. The stuff burns real well and turns from a handful of powder into a huge volume of white hot gas in half a millisecond. This pressure pushes the bullet down the barrel. The pressure exerted is tremendous, sometimes reaching a peak of 65,000psi. While the steel used in a modern rifle can withstand more than 120,000psi, the brass case of a cartridge has an elastic strength of no more than 75,000psi. So you can see where jacking up the engraving pressure by 10 to 20,000psi could lead to problems. Back to the drawing board.

The solution came from looking forward into the past. At first, various lubrication coatings were tried. After all, that worked for cast lead bullets 120 years ago. “Moly” (molybdenum disulphide) was tried, along with Teflon™ and several others. They worked. Sort of. They were good at reducing friction as the bullet traveled down the barrel, but couldn’t do a thing to reduce engraving pressure. A better fix was needed. And the fix was found by Gerard Schultz of GS Custom Bullets of South Africa. Who looked forward into the past, and realized that the “driving band” technology used on artillery shells for the last 150 years could be used on bullets too, but only if those bullets were cut on a lathe. Driving band technology? WTH? Artillery shells are made of iron or steel. Both of which are much, much harder and less malleable than copper. It is just about impossible to engrave one on the steel rifling in a cannon barrel without wearing the barrel out in a very short time. So artillery shells are made quite a bit undersize relative to the barrel they get fired in. They are all “bore riding” designs. (to make a rifled barrel, first you bore a hole in the steel, then you cut away the rifling grooves from the outside of the hole. This means that a rifled barrel actually has two hole diameters, the bore {or “land"} diameter, and the slightly larger groove diameter. On a rifle that difference is usually about 0.008”. On a cannon barrel it can be nearly half an inch for the big guns) The shells get a few copper bands tightly wrapped around them at the factory, and it is those driving bands that get engraved with the rifling. And also seal the bore so that the powder gases don’t leak past the projectile. Think of them as the rings on a piston. It works great, but the concept was impossible to apply to bullets, especially small ones. Once Schultz pointed out the obvious fact that they could be added to lathe cut bore riding design bullets everyone else jumped on the bandwagon. GS Custom still does it best by using the most minimal and most aerodynamic bands, but the squared off bands the other companies use work almost as well (see the picture at the top of the page), and are probably less expensive to make. The Barnes company turns the concept inside out and just cuts a few grooves in their copper bullets. That works too. The whole idea works because copper and it’s alloys are much firmer than lead, and a few driving bands are enough to properly support the bullet in the barrel. Using just enough support for the bullet results in a whole lot less friction in the barrel and allows for much more normal engraving pressures. Problem solved.

So, two problems down, several more to go. I’ve already mentioned that copper bullets are longer for a given weight, shape, and diameter. This gives them what physicists call a “longer moment arm”, and in the real world that means that they have to be spun a bit faster to be properly stabilized. Very long nose ogives, like the Von Kármán-Haack design on the GS Custom bullet shown, give great aerodynamics but also require more spin. So the gun makers have begun to build rifles with faster pitch rifling. You AR-15 shooters know all about this already, but it’s carrying over to other barrels as well. The ancient Greenhill Formula, used to determine the minimum rifling pitch for a bullet in the air, is dead, dying, or at least needs some extension. Not that it really matters too much, as the gun makers have been using faster and faster rifling pitches for a long time now. And it turns out fortuitously that faster twist allows any bullet to penetrate it’s target in a straighter line. Well duh, really, since flesh is many times denser than air ... and Greenhill can be extended to show that the optimal twist rate for shooting in water is about one turn in 3”. So the 1:9 to 1:12 twist rate most barrels have today is much more effective than the 1:66 to 1:20 twist rates from way back when. But if you are building a rifle to shoot these long modern lead free bullets you want as tight a twist as you can get. 1:7 to 1:9 is about right for most situations. Problem solved by the barrel makers.

Are we ever going to get to the freakin’ supercavitation bit Drew? Jumping Jeebus on a pogo stick, you wrote a whole friggin’ book just to get this far. Yeah, I know. This is one of those long winded posts that I write about things that really interest me. The ones where I’ve done hours and hours of research and have dozens of links I won’t even use. But I’m doing my best to boil it all down so that readers who don’t know beans about firearms will understand why the Woodleigh bullet I’m writing about really is such an exciting advance. Bear with me, it’s coming soon. I’m trying.

The theory of supercavitation is not new. It exists because all fluids, from air to water to flesh, can be considered laminar in nature. Layered. Aerodynamics is the study of how to minimize the disturbance to those layers. Supercavitation theorizes that by abruptly disturbing a small fluid layer out ahead of your moving body a laminar pocket can be formed that will smoothly go around your moving body and thus drastically reduce the friction that would otherwise act upon it while it moves through that medium. In other words it will go faster for longer with less drag. It’s real. Dolphins use it. They actually fly through the water inside a curtain of micro-bubbles of air. The military has been using it for a long time now on missiles and certain types of artillery shells. These days there are torpedoes that travel through the water at over 230mph. And that’s slow compared to the Mach 1 rocket driven torpedoes under development. Supercavitation works.

But the theory has been difficult to apply to bullets. Let’s face it, even the big ones are still pretty tiny things. When your moving body is hardly a third of an inch in diameter and only a little over an inch long ( and spinning at 300,000rpm ) there isn’t much room for strapping on high-tech doodads. Even the Navy’s RAMICS projectile, 30mm in diameter, is much larger. So it had to come from design.

As far as I can find out, much of the fundamental work of developing a supercavitating hunting bullet was done by Norbert Hansen about a decade ago. He may have had quite a lot of knowledge gleaned from the military, but he worked things out with math, patience, and a really good lathe. And it worked.

So now we are finally back to the Woodleigh bullet. Solid copper alloy. Driving band bore rider technology for minimal barrel friction. Short ogive nose for reduced tumbling and normal rifling. Supercavitation design for maximum penetration. Lead-free “green” design. Pretty damn impressive. As I said, it’s the dawn of the 7th generation of bullets. And it works.

Why does anyone need a supercavitating bullet in the first place? Because elephants are about 8 feet thick. And Cape Buffalo are about 4 feet thick. And you rarely get a perfect broadside shot, so you need every last bit of penetration you can get.

Ok, so why not use a blunt? A flat nosed, non-expanding solid, whether it’s a hard cast Elmer Keith style, or one of the high-tech blunts that GS Custom makes?

Because, as the picture on the right show, either one of them will deform. And while that deforming, called mushrooming in the world of bullets, will carve a large wound channel, it will slow the bullet down tremendously and imbalance it. Which means eventually it will bend from it’s path while penetrating. Which means you might be aiming at the heart, but the bullet winds up in the tail. This happens frequently when shooting at the largest of creatures. Also, standard blunt bullets like this only create a permanent wound channel slightly larger than their own diameter, unlike typical expanding bullets. You might find it harsh to think about, but an ethical hunter wants to create the largest possible wound in the creature he’s shooting, to kill it as fast as possible. Modern expanding bullets do a fantastic job of this, but at the cost of overall penetration. Which is fine, as deer and antelope are barely a foot to a foot and a half thick. You don’t need all that much penetration for a broadside shot at them, but you do want to “use enough gun” so that your bullet will reach their vitals from any angle and have enough oomph left to do the job. Bullet selection is always a trade off. Always. But when you may have to shoot through 7 or 8 feet of angry animal to get to the killing zone, you want every last bit of straight line penetration you can get. And if you can get a bigger permanent wound channel in the process, all the better. The supercavitating bullet drives straight through, creates a larger wound channel than a typical blunt, and then the leading pressure wave tears out a massive chunk of flesh on exit. That’s as good as it gets. It’s probably useless on deer, but bullets are a very niche item these days. In it’s own niche, I think this one is supreme.

To me, the first bullet in the gel pack photo above is obviously a Barnes XFN. Obvious because that’s exactly the size and shape of a wound channel that the XFN bullet makes. If you would like to learn about how bullets actually work on game, the whole world of terminal ballistics, and why Woodleigh’s “hydrostatically stabilised” name is a deliberate misnomer that caters to a poorly educated shooting audience, please spend an hour or two and read the Terminal Ballistics treatise written by my digital friend Ulf. You will never think of bullets the same way again, guaranteed. Or you just click here, zoom to the very end and look at the picture, where you’ll see that his test results diagram of the Barnes bullet is exactly like the top one in the above picture.

You can read a bit more about the Woodleigh bullet in their new catalog. Click here. But be forewarned that there are some pictures of bloody dead animals in it, including the large chunk of flesh I mentioned above. Come to think of it, if you follow the links from Hansen’s pages you will see some blood and guts too.

If you’ve read through this whole post, and followed the links and read those pages and done the same for a few of the links they contain, you should now consider yourself an expert on the behavior of bullets at the target end of things. For a whole lot of information on how they behave in flight and in the gun, plus a huge pile of info on reloading and the capabilities of most of the safari cartridges new and old, pick up a copy of Art Alphin’s Any Shot You Want loading manual and read it several times. You can learn about the art of paper patching online, or you can pick up a copy of Paul Matthews The Paper Jacket if you can hunt one down. It’s the very best, but it’s out of print right now. Amazon has a few copies left.

Posted by Drew458

Filed Under: • Guns and Gun Control • High Tech •

• Comments (6)

Thursday - March 04, 2010

Thursday - March 04, 2010

Those wacky Japanese…

Seems the world-wide recession has even hit Japanese pet owners. Instead of sending their pets to the usual pet groomers, they’ve opted for the pet washing machines

Japanese pet owners are trying to save money in today’s recession by having their dogs and cats washed in a specially designed machine instead of using groomers.

More and more people in the suburbs of Tokyo are using the vending machines that wash, rinse and blow dries their pets in about 30 minutes, Ananova reports.

A groomer at Joyful Honda pet market claims the process uses pure ozone water and is completely safe for the pet. One user, however, admitted it took his Yorkshire terrier a while to get used to the dryer.

The vending machine wash costs about $5 compared to approximately $30 for grooming.

Small print: $150 may be needed for pet therapy afterward.

Why yes! Thank you for asking. There is a video:

Posted by Christopher

Filed Under: • Animals • High Tech • Humor •

• Comments (10)

Wednesday - January 06, 2010

Wednesday - January 06, 2010

No More Bat Boat

Personally, I’m not in favor of whale hunting. Leave them alone. You want meat, grow a few hundred cattle. That being said, the “whale warriors” have to be the most annoying greenies out there. They have their own television program ... in which they take pictures of themselves harassing Japanese fishermen and fishing boats. Lately these “warriors” have turned somewhat violent, pelting the fishing boats with chum, water balloons, paint guns, etc. The fishermen respond with the standard anti-piracy tool: fire hoses. Reality TV drama with a green theme! Much more exciting than watching guys catch crabs in the dark!!

Well, the inevitable happened. The Save The Whales people put their super hi-tech speedboat in front of a full size ship, and stopped. The whaling ship was underway. Ships don’t have brakes you know. I remember a little bit from driver training, about the impact power of things out on the streets: bicycle beats pedestrian, motorcycle beats bicycle, car beats motorcycle, pickup truck beats car, bigger truck beats pickup truck, bus beats bigger truck, train beats bus. And you know what beats train? Ships. And bigger ships beat smaller ones. Oh sure, rules of the road say that pedestrians always have the right of way ... but don’t be a dope and set out to prove it. Rules of the sea say that a kayak probably has right of way over anything else on the water too ... but you’d be a fool to force the issue with an air craft carrier.

The “whale warriors” decided to force the issue. Naturally they lost. Boo frickin’ hoo. And now their two million dollar batman boat is all stove in. tsk tsk tsk. On the other hand, leave the whales the hell alone. Go catch some stingrays if you’re hungry. We’ve got loads of them. Or start up a fish farm like everyone else is doing. So honestly ... I’m not sure which side I’m on here. But the “whale warriors” seem like floating stinky hippies to me, so they probably deserve punching just on general principle.

A conservation group’s boat had its bow sheared off and was in danger of sinking as it took on water Wednesday after it was struck by a Japanese whaling ship in the frigid waters of Antarctica, the group said.

The boat’s six crew members were safely transferred to another of the Sea Shepherd Conservation Society’s vessels, the newly commissioned Bob Barker. The boat is named for the American game show host who donated $5 million to buy it.

The clash was the most serious in the past several years, during which the Sea Shepherd has sent vessels into far-southern waters to try to harass the Japanese fleet into ceasing its annual whale hunt.

Clashes using hand-thrown stink bombs, ropes meant to tangle propellers and high-tech sound equipment have been common in recent years, and crashes between ships have sometimes occurred.

The society said its vessel Ady Gil — a high-tech speedboat that resembles a stealth bomber — was hit by the Japanese ship the Shonan Maru near Commonwealth Bay and had about 10 feet (three meters) of its bow knocked off.

Locky Maclean, the first mate of the society’s lead ship, said one crewman from New Zealand appeared to have suffered two cracked ribs, but the others were uninjured. The crew members were safely transferred to the group’s third vessel, though the Ady Gil’s captain remained on board to see what could be salvaged, he said.

The group accused the Japanese ship of deliberately ramming the Ady Gil.

“They were stopped dead in the water when the incident occurred,” Maclean said of the Ady Gil. “When they realized that the Shonan Maru was aiming right for them, they tried to go into reverse to get the bow out of the way but it was too late. The Shonan Maru made a course correction and plowed directly into the front end of the boat.”

The Sea Shepherd Conservation Society claimed its 78 ft protest powerboat the Ady Gil was “sliced in half” by the Japanese security ship Shonan Maru 2 as it loitered near the whaling fleet.

Jeff Hansen, the group’s director, insisted the Ady Gil was trying to get out of the way when it was hit, but Japan’s government-backed Institute of Cetacean Research (ICR) has accused the protesters of causing the collision. Mr Hansen said the incident occurred after two activist vessels intercepted the Japanese fleet near Antarctica’s Commonwealth Bay.

“The Ady Gil has been cut, hit by one of the harpoon vessels,” he said. “It was stationary at the time. It tried to back out of the way but the Shonan Maru 2 had it in its path. It came through and took off a section off the fuselage.”

There wreckage of the boat was still afloat, but it was expected to sink in the next few hours as it took on water, he said. All six crew members had been rescued and transferred to Sea Shepherd’s new Norwegian harpoon ship the Bob Barker. “Everyone aboard is safe, we’ve managed to get everyone off and they’re ok,” Mr Hansen told Australian media.

“We have it all on film and we’re getting onto all the authorities at the moment.”

Paul Watson, captain and founder of Sea Shepherd, said the attack “seriously escalates the whole situation”.

“If they think that our remaining two ships will retreat from the Southern Ocean Whale Sanctuary in the face of their extremism, they will be mistaken,” he said. “We now have a real whale war on our hands now and we have no intention of retreating.”

The activists have a ship named the Bob Barker? Yeah, him. Mr. Gameshow host, Bob “have your pets spayed or neutered” Barker. They have another craft named the Steve Irwin. Crikey.

When it [ the Ady Gil ] was launched on Dec 19, the $1.5 million carbon fibre trimaran was touted as Sea Shepherd’s secret weapon. The Ady Gil was designed to run on low-emission, renewable fuels and was built with materials that would make it difficult for radars to detect so that it could sneak up of whaling vessels and disrupt the hunt. But its lighweight design, which allowed the vessel to reach higher speeds than the group’s larger ships, meant it was far less robust and more susceptible to attack.

This was the maiden voyage of the Ady Gil. Previously known as the EarthRace, it’s a very high performance open ocean racing boat. “Couldn’t get out of the way in time”? Horseshit. EarthRace holds the record for the fastest motorboat trip around the globe; just under 61 days. On two tanks full of fuel I gather. 78 feet long, but only drawing 4 feet of water, the EarthRace could hit 40 knots with it’s 1040hp engines and it’s dry weight of only 14 tons.

(October 18, 2009) At a fundraising event in Los Angeles on Saturday, the Sea Shepherd Conservation Society unveiled their newest “ocean defense” vessel: the Ady Gil. Formerly known as Earthrace, the ship was renamed to honor the benefactor that helped the anti-whaling group acquire the ship.

“We’re very excited that the Ady Gil will be joining the Steve Irwin in Antarctica this campaign,” Captain Paul Watson said. “With these two ships, we will mount the most ambitious and aggressive effort to date to obstruct the slaughter of the whales in the Southern Ocean.”

We’ve been following the transformation of the Earthrace/Gil from a world-record holding speedboat to an anti-whaling vessel since it was rumored back in April that it would be joining the Sea Shepherd fleet. With the new paint job and a few additional high-tech goodies now installed, it looks like the ship is ready to join the Irwin for Operation Waltzing Matilda this December.

As expected, Watson made it clear that he intends to place the Gil in harms way — particularly as an “intercept and blocking” weapon against the Japanese fleet. Sounds like a risky game of “chicken” — but Ady Gil Captain Pete Bethune is ready for the challenge.”If they ever hit us with an explosive harpoon it’ll be massive damage,” he told Ecorazzi during the summer. “But certainly we’ll do our best to get in their way. If they hit us it will always be their guy that pulled the trigger — but hopefully things won’t come to that.”

Consider yourselves fortunate that the fishermen didn’t hunt you down and kill you. I’m sure it was very tempting.

Commercial whaling is banned inthe Southern Ocean, but the Japanese have exploited a legal loophole to continue whaling for “scientific purposes”. This season the Japanese fleet aims to harpoon up to 935 minke whales and 50 fin whales, both of which are classified as endangered.

Minke whales and Fin whales are both baleen whales, like their cousins the Humpbacks and the Blues. Minkes are rather small, about 24 feet and 9 tons. Fins are the second largest creature on earth, reaching 88 feet and 75 tons. Both are endangered species, although the minke population is thought to exceed 900,000 worldwide, roughly 30 times the fin whale population. Actually, minkes may not be endangered; it’s hard to tell.

Is Japan full of it? I think so. You don’t need to kill whales to study them. Certainly not by the hundreds. And you especially don’t need to kill any of the seriously endangered ones. None. But stopping whaling altogether? Or at least stopping commercial, floating factory whaling? Sounds to me like this is a job for the UN and the One World Navy. Not a job for floating hippies in their little plastic speedboats.

UPDATE: Video from the whaler’s perspective here.

Posted by Drew458

Filed Under: • Animals • High Tech • Politically-Incorrect •

• Comments (6)

Five Most Recent Trackbacks:

Once Again, The One And Only Post

(4 total trackbacks)

Tracked at iHaan.org

The advantage to having a guide with you is thɑt an expert will haѵe very first hand experience dealing and navigating the river with гegional wildlife. Tһomas, there are great…

On: 07/28/23 10:37

The Brownshirts: Partie Deux; These aare the Muscle We've Been Waiting For

(3 total trackbacks)

Tracked at head to the Momarms site

The Brownshirts: Partie Deux; These aare the Muscle We’ve Been Waiting For

On: 03/14/23 11:20

Vietnam Homecoming

(1 total trackbacks)

Tracked at 广告专题配音 专业从事中文配音跟外文配音制造,北京名传天下配音公司

专业从事中文配音和外文配音制作,北京名传天下配音公司 北京名传天下专业配音公司成破于2006年12月,是专业从事中 中文配音 文配音跟外文配音的音频制造公司,幻想飞腾配音网领 配音制作 有海内外优良专业配音职员已达500多位,可供给一流的外语配音,长年服务于国内中心级各大媒体、各省市电台电视台,能满意不同客户的各种需要。电话:010-83265555 北京名传天下专业配音公司…

On: 03/20/21 07:00

meaningless marching orders for a thousand travellers ... strife ahead ..

(1 total trackbacks)

Tracked at Casual Blog

[...] RTS. IF ANYTHING ON THIS WEBSITE IS CONSTRUED AS BEING CONTRARY TO THE LAWS APPL [...]