Thursday - May 27, 2010

Thursday - May 27, 2010

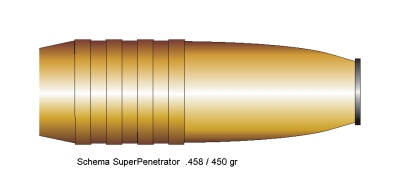

High Tech Hunting Bullet

That picture may not look like much to most folks, but there is an impressive amount of science behind this bullet. What you are looking at is the dawn of the 7th generation of consumer firearms projectiles. Not only is this bullet “green”, it can also shoot through water for a considerable distance, which no other bullet has ever been able to do. When used against dangerous game - very large animals that may be actively trying to kill you while you are actively trying to kill them - it is designed to out-penetrate every other kind of bullet on the market and to create a larger wound channel than any other “solid”. It’s the best of all worlds in it’s own little specialized niche. Woodleigh is a bullet making company in Australia.

This is an elephantine post about an elephant bullet. If you don’t want the technology lecture and the history lesson on bullet design you can skip ahead to the end. Or go on to the next post, which may have titties. Or not.

In the beginning, back before John Moses Browning (PBUH) created the world as we know it, there was the lead ball. You poured a charge of black powder down the long thin barrel of your musket, wrapped a bit of greased cloth around the big lead ball, and stuffed it down the tube. When fired, it accelerated to about 900 feet per second and generally went forward. If the distance was very short, say less than 75 yards, you would hit what you were aiming at, mostly, and the big soft lead ball would put a large hole in it. Providing that what you were shooting at wasn’t really thick; unrifled muskets don’t put any spin on the ball, so the round bullet isn’t stabilized at all, and has no forces acting on it to help it burrow in in a straight line. But lead is soft, and that 3/4” diameter ball squashed itself out to 1 1/2” across on impact, and created a pretty damn big, if shallow, hole. And that was enough. Unless you were hunting bears or lions or big angry buffalo, in which case you wanted half a dozen friends along with their own muskets so they could shoot too. And then you could all run in different directions, and hope that the critter chose to chase someone else.

At some later point rifling was invented. Exactly like the threads on a screw, but with a much longer spiral, rifling imparts an axial spin to a bullet as it is fired down the barrel. This made that ball fly much straighter, which allowed those primitive boomsticks to have some degree of accuracy for the first time. The spinning also caused the ball to penetrate much further, or at least straighter. It was a big step forward. Now you only needed a couple of friends along.

Pointed bullets came next. Conical projectiles, the Minie ball. Paper patching, lubricated grooved bullets, better metallurgy, better casting, harder alloys of lead and tin and antimony, a bit of aerodynamics, and soon thereafter reliable weather resistant metallic cartridges, repeating rifles, smokeless gunpowder with a whole lot more energy. There was a tremendous technical leap forward in the 30 year period from 1860 to 1890. So much progress that the old raw lead bullet could not (literally) take the pressure, and would smear itself to pieces inside the barrel upon firing.

So the chunk of lead got squeezed into a copper jacket. “Gilding metal”, a soft and smooth brass alloy, soon replaced copper. A few years later it was found that the “spitzer” shape, a pointed bullet with a mathematically derived pointed ogive on the front, was highly aerodynamic. This allowed bullets to to be accurate to extraordinary ranges and to retain considerable kinetic energy all the way there. The modern rifle was born. 110 years ago.

In the interim folks have fussed and tweaked with the design of the bullet. A longer point, a shorter point. Flat base, tapered base (ie boat tail) Exposed lead tips vs. full metal jackets. Lead cores cast in place in their jackets, glued in, electrochemically bonded in, locked in place with swaged grooves. Different thicknesses and hardnesses of the metal jacket. Bronze points, plastic points, steel and tungsten rods inserted in the lead cores. All attempting to build a bullet that worked the best on a certain sized creature at a certain velocity range. And with pretty good success too; there is an amazing variety of very effective bullets on the market today, so many that it’s almost work trying to figure out which one is the best for your hunting trip. Bullets have become highly specialized.

A few decades ago solid copper and bronze bullets came on the market. This is where the “green” part comes in, tangentially. Environmentalists have been quite successful in getting lead shotgun pellets banned in many places. Lead has always been used for shot pellets and for bullets, because it is very dense, malleable, abundant, and cheap. But when you shoot at some birds with your shotgun, not all the pellets hit. Some fall to the ground or into the water, where a poor little birdie or fishy might eat them. And get lead poisoning. It’s a helluva stretch, but it is just barely conceivable. And it shows you just how much political power the anti-gun, anti-hunting brigade really has. So the shotgun ammunition world is moving away from lead shot, using steel, bismuth, or tungsten pellets instead. The bullet makers can read the writing on the wall, and now lead-free, solid copper alloy bullets are all the rage. Primers don’t even use lead styphnate (C6HN3O8Pb any more because that’s a “toxic explosive” and you mustn’t be exposed to even microscopic amounts of lead vapor. God forbid actual lead. So let’s use copper bullets. “Problem” solved.

So, while “green”, copper bullets have a whole pile of issues of their own. Copper is much less dense than lead, so a bullet of a certain size and shape will weigh a lot less. Which means that at equal velocity it will carry much less kinetic energy; it will not have as much power. Conversely, copper bullets of equal weight to their lead cored counterparts will be much longer, and may not chamber properly in the magazine or the chamber throat of the firearm. Sure, easy, seat them deeper into the case. But that takes up a lot of internal volume that the gun powder used to use. Copper is also much harder than lead, and solid copper is much less malleable than the thinly jacketed bullets we’ve been using for 100 years. This makes the engraving process - the act, upon firing, where the suddenly accelerating bullet is forced out of the cartridge case and into the barrel’s rifling lands and grooves - much more difficult, and that raises chamber pressures. Chamber pressure is what you get when you light off a charge of gun powder inside your gun. The stuff burns real well and turns from a handful of powder into a huge volume of white hot gas in half a millisecond. This pressure pushes the bullet down the barrel. The pressure exerted is tremendous, sometimes reaching a peak of 65,000psi. While the steel used in a modern rifle can withstand more than 120,000psi, the brass case of a cartridge has an elastic strength of no more than 75,000psi. So you can see where jacking up the engraving pressure by 10 to 20,000psi could lead to problems. Back to the drawing board.

The solution came from looking forward into the past. At first, various lubrication coatings were tried. After all, that worked for cast lead bullets 120 years ago. “Moly” (molybdenum disulphide) was tried, along with Teflon™ and several others. They worked. Sort of. They were good at reducing friction as the bullet traveled down the barrel, but couldn’t do a thing to reduce engraving pressure. A better fix was needed. And the fix was found by Gerard Schultz of GS Custom Bullets of South Africa. Who looked forward into the past, and realized that the “driving band” technology used on artillery shells for the last 150 years could be used on bullets too, but only if those bullets were cut on a lathe. Driving band technology? WTH? Artillery shells are made of iron or steel. Both of which are much, much harder and less malleable than copper. It is just about impossible to engrave one on the steel rifling in a cannon barrel without wearing the barrel out in a very short time. So artillery shells are made quite a bit undersize relative to the barrel they get fired in. They are all “bore riding” designs. (to make a rifled barrel, first you bore a hole in the steel, then you cut away the rifling grooves from the outside of the hole. This means that a rifled barrel actually has two hole diameters, the bore {or “land"} diameter, and the slightly larger groove diameter. On a rifle that difference is usually about 0.008”. On a cannon barrel it can be nearly half an inch for the big guns) The shells get a few copper bands tightly wrapped around them at the factory, and it is those driving bands that get engraved with the rifling. And also seal the bore so that the powder gases don’t leak past the projectile. Think of them as the rings on a piston. It works great, but the concept was impossible to apply to bullets, especially small ones. Once Schultz pointed out the obvious fact that they could be added to lathe cut bore riding design bullets everyone else jumped on the bandwagon. GS Custom still does it best by using the most minimal and most aerodynamic bands, but the squared off bands the other companies use work almost as well (see the picture at the top of the page), and are probably less expensive to make. The Barnes company turns the concept inside out and just cuts a few grooves in their copper bullets. That works too. The whole idea works because copper and it’s alloys are much firmer than lead, and a few driving bands are enough to properly support the bullet in the barrel. Using just enough support for the bullet results in a whole lot less friction in the barrel and allows for much more normal engraving pressures. Problem solved.

So, two problems down, several more to go. I’ve already mentioned that copper bullets are longer for a given weight, shape, and diameter. This gives them what physicists call a “longer moment arm”, and in the real world that means that they have to be spun a bit faster to be properly stabilized. Very long nose ogives, like the Von Kármán-Haack design on the GS Custom bullet shown, give great aerodynamics but also require more spin. So the gun makers have begun to build rifles with faster pitch rifling. You AR-15 shooters know all about this already, but it’s carrying over to other barrels as well. The ancient Greenhill Formula, used to determine the minimum rifling pitch for a bullet in the air, is dead, dying, or at least needs some extension. Not that it really matters too much, as the gun makers have been using faster and faster rifling pitches for a long time now. And it turns out fortuitously that faster twist allows any bullet to penetrate it’s target in a straighter line. Well duh, really, since flesh is many times denser than air ... and Greenhill can be extended to show that the optimal twist rate for shooting in water is about one turn in 3”. So the 1:9 to 1:12 twist rate most barrels have today is much more effective than the 1:66 to 1:20 twist rates from way back when. But if you are building a rifle to shoot these long modern lead free bullets you want as tight a twist as you can get. 1:7 to 1:9 is about right for most situations. Problem solved by the barrel makers.

Are we ever going to get to the freakin’ supercavitation bit Drew? Jumping Jeebus on a pogo stick, you wrote a whole friggin’ book just to get this far. Yeah, I know. This is one of those long winded posts that I write about things that really interest me. The ones where I’ve done hours and hours of research and have dozens of links I won’t even use. But I’m doing my best to boil it all down so that readers who don’t know beans about firearms will understand why the Woodleigh bullet I’m writing about really is such an exciting advance. Bear with me, it’s coming soon. I’m trying.

The theory of supercavitation is not new. It exists because all fluids, from air to water to flesh, can be considered laminar in nature. Layered. Aerodynamics is the study of how to minimize the disturbance to those layers. Supercavitation theorizes that by abruptly disturbing a small fluid layer out ahead of your moving body a laminar pocket can be formed that will smoothly go around your moving body and thus drastically reduce the friction that would otherwise act upon it while it moves through that medium. In other words it will go faster for longer with less drag. It’s real. Dolphins use it. They actually fly through the water inside a curtain of micro-bubbles of air. The military has been using it for a long time now on missiles and certain types of artillery shells. These days there are torpedoes that travel through the water at over 230mph. And that’s slow compared to the Mach 1 rocket driven torpedoes under development. Supercavitation works.

But the theory has been difficult to apply to bullets. Let’s face it, even the big ones are still pretty tiny things. When your moving body is hardly a third of an inch in diameter and only a little over an inch long ( and spinning at 300,000rpm ) there isn’t much room for strapping on high-tech doodads. Even the Navy’s RAMICS projectile, 30mm in diameter, is much larger. So it had to come from design.

As far as I can find out, much of the fundamental work of developing a supercavitating hunting bullet was done by Norbert Hansen about a decade ago. He may have had quite a lot of knowledge gleaned from the military, but he worked things out with math, patience, and a really good lathe. And it worked.

So now we are finally back to the Woodleigh bullet. Solid copper alloy. Driving band bore rider technology for minimal barrel friction. Short ogive nose for reduced tumbling and normal rifling. Supercavitation design for maximum penetration. Lead-free “green” design. Pretty damn impressive. As I said, it’s the dawn of the 7th generation of bullets. And it works.

Why does anyone need a supercavitating bullet in the first place? Because elephants are about 8 feet thick. And Cape Buffalo are about 4 feet thick. And you rarely get a perfect broadside shot, so you need every last bit of penetration you can get.

Ok, so why not use a blunt? A flat nosed, non-expanding solid, whether it’s a hard cast Elmer Keith style, or one of the high-tech blunts that GS Custom makes?

Because, as the picture on the right show, either one of them will deform. And while that deforming, called mushrooming in the world of bullets, will carve a large wound channel, it will slow the bullet down tremendously and imbalance it. Which means eventually it will bend from it’s path while penetrating. Which means you might be aiming at the heart, but the bullet winds up in the tail. This happens frequently when shooting at the largest of creatures. Also, standard blunt bullets like this only create a permanent wound channel slightly larger than their own diameter, unlike typical expanding bullets. You might find it harsh to think about, but an ethical hunter wants to create the largest possible wound in the creature he’s shooting, to kill it as fast as possible. Modern expanding bullets do a fantastic job of this, but at the cost of overall penetration. Which is fine, as deer and antelope are barely a foot to a foot and a half thick. You don’t need all that much penetration for a broadside shot at them, but you do want to “use enough gun” so that your bullet will reach their vitals from any angle and have enough oomph left to do the job. Bullet selection is always a trade off. Always. But when you may have to shoot through 7 or 8 feet of angry animal to get to the killing zone, you want every last bit of straight line penetration you can get. And if you can get a bigger permanent wound channel in the process, all the better. The supercavitating bullet drives straight through, creates a larger wound channel than a typical blunt, and then the leading pressure wave tears out a massive chunk of flesh on exit. That’s as good as it gets. It’s probably useless on deer, but bullets are a very niche item these days. In it’s own niche, I think this one is supreme.

To me, the first bullet in the gel pack photo above is obviously a Barnes XFN. Obvious because that’s exactly the size and shape of a wound channel that the XFN bullet makes. If you would like to learn about how bullets actually work on game, the whole world of terminal ballistics, and why Woodleigh’s “hydrostatically stabilised” name is a deliberate misnomer that caters to a poorly educated shooting audience, please spend an hour or two and read the Terminal Ballistics treatise written by my digital friend Ulf. You will never think of bullets the same way again, guaranteed. Or you just click here, zoom to the very end and look at the picture, where you’ll see that his test results diagram of the Barnes bullet is exactly like the top one in the above picture.

You can read a bit more about the Woodleigh bullet in their new catalog. Click here. But be forewarned that there are some pictures of bloody dead animals in it, including the large chunk of flesh I mentioned above. Come to think of it, if you follow the links from Hansen’s pages you will see some blood and guts too.

If you’ve read through this whole post, and followed the links and read those pages and done the same for a few of the links they contain, you should now consider yourself an expert on the behavior of bullets at the target end of things. For a whole lot of information on how they behave in flight and in the gun, plus a huge pile of info on reloading and the capabilities of most of the safari cartridges new and old, pick up a copy of Art Alphin’s Any Shot You Want loading manual and read it several times. You can learn about the art of paper patching online, or you can pick up a copy of Paul Matthews The Paper Jacket if you can hunt one down. It’s the very best, but it’s out of print right now. Amazon has a few copies left.

Posted by Drew458

Filed Under: • Guns and Gun Control • High Tech •

• Comments (6)

Five Most Recent Trackbacks:

Once Again, The One And Only Post

(4 total trackbacks)

Tracked at iHaan.org

The advantage to having a guide with you is thɑt an expert will haѵe very first hand experience dealing and navigating the river with гegional wildlife. Tһomas, there are great…

On: 07/28/23 10:37

The Brownshirts: Partie Deux; These aare the Muscle We've Been Waiting For

(3 total trackbacks)

Tracked at head to the Momarms site

The Brownshirts: Partie Deux; These aare the Muscle We’ve Been Waiting For

On: 03/14/23 11:20

Vietnam Homecoming

(1 total trackbacks)

Tracked at 广告专题配音 专业从事中文配音跟外文配音制造,北京名传天下配音公司

专业从事中文配音和外文配音制作,北京名传天下配音公司 北京名传天下专业配音公司成破于2006年12月,是专业从事中 中文配音 文配音跟外文配音的音频制造公司,幻想飞腾配音网领 配音制作 有海内外优良专业配音职员已达500多位,可供给一流的外语配音,长年服务于国内中心级各大媒体、各省市电台电视台,能满意不同客户的各种需要。电话:010-83265555 北京名传天下专业配音公司…

On: 03/20/21 07:00

meaningless marching orders for a thousand travellers ... strife ahead ..

(1 total trackbacks)

Tracked at Casual Blog

[...] RTS. IF ANYTHING ON THIS WEBSITE IS CONSTRUED AS BEING CONTRARY TO THE LAWS APPL [...]

On: 07/17/17 04:28

a small explanation

(1 total trackbacks)

Tracked at yerba mate gourd

Find here top quality how to prepare yerba mate without a gourd that's available in addition at the best price. Get it now!

On: 07/09/17 03:07

DISCLAIMER

THE SERVICES AND MATERIALS ON THIS WEBSITE ARE PROVIDED "AS IS" AND THE HOSTS OF THIS SITE EXPRESSLY DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OR IMPLIED, TO THE EXTENT PERMITTED BY LAW INCLUDING BUT NOT LIMITED TO WARRANTIES OF SATISFACTORY QUALITY, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO THE SERVICE OR ANY MATERIALS.

Not that very many people ever read this far down, but this blog was the creation of Allan Kelly and his friend Vilmar. Vilmar moved on to his own blog some time ago, and Allan ran this place alone until his sudden and unexpected death partway through 2006. We all miss him. A lot. Even though he is gone this site will always still be more than a little bit his. We who are left to carry on the BMEWS tradition owe him a great debt of gratitude, and we hope to be able to pay that back by following his last advice to us all:

It's been a long strange trip without you Skipper, but thanks for pointing us in the right direction and giving us a swift kick in the behind to get us going. Keep lookin' down on us, will ya? Thanks.

- Keep a firm grasp of Right and Wrong

- Stay involved with government on every level and don't let those bastards get away with a thing

- Use every legal means to defend yourself in the event of real internal trouble, and, most importantly:

- Keep talking to each other, whether here or elsewhere

THE INFORMATION AND OTHER CONTENTS OF THIS WEBSITE ARE DESIGNED TO COMPLY WITH THE LAWS OF THE UNITED STATES OF AMERICA. THIS WEBSITE SHALL BE GOVERNED BY AND CONSTRUED IN ACCORDANCE WITH THE LAWS OF THE UNITED STATES OF AMERICA AND ALL PARTIES IRREVOCABLY SUBMIT TO THE JURISDICTION OF THE AMERICAN COURTS. IF ANYTHING ON THIS WEBSITE IS CONSTRUED AS BEING CONTRARY TO THE LAWS APPLICABLE IN ANY OTHER COUNTRY, THEN THIS WEBSITE IS NOT INTENDED TO BE ACCESSED BY PERSONS FROM THAT COUNTRY AND ANY PERSONS WHO ARE SUBJECT TO SUCH LAWS SHALL NOT BE ENTITLED TO USE OUR SERVICES UNLESS THEY CAN SATISFY US THAT SUCH USE WOULD BE LAWFUL.

Copyright © 2004-2015 Domain Owner

Oh, and here's some kind of visitor flag counter thingy. Hey, all the cool blogs have one, so I should too. The Visitors Online thingy up at the top doesn't count anything, but it looks neat. It had better, since I paid actual money for it.