Tuesday - August 12, 2008

Tuesday - August 12, 2008

.45-60 Blogging: The 2 Cent Machine Shop

Ok. Last week I took a cut down .45-70 down to my chiropractor to test fit on his new Uberti 1876 in .45-60. While the action closed on the case, it was rather tight. This week I took in another case that I had thinned the front part of the rim down by a few thousandths. The action closed much easier. Question answered.

What question? According to the cartridge specifications, the .45-60 was designed to have a rim that was 0.059” thick. The .45-70 was designed to have a rim 0.070” thick. While the .45-60 is essentially a defunct round these days, the 135 year old .45-70 is still quite popular. The brass cases however, are almost always made with rims thinner than specified. They average 0.064”. Is that an Ok thickness for the .45-60, or does that one want something thinner?

Ok, so to make .45-60 cases for this Uberti the rims need to be thinned. I did the first two by hand, with a file and a power drill. There used to be a saying in the computer world: “Do a task once, do it manually. Do it twice, develop a process. Do it three times or more, write a program.” The same concept applies to making things. Especially if you want them all identical. Since my doc is going to want 100 or so cases, it was time to build a machine. Hmm ... what to do? If I only had a Unimat milling machine! Yeah right, for $500? Not happening.

He has a drill press. Super! Set up properly, a drill press is almost as good as a milling machine or a lathe. So let’s think this through ...

- A good production tool has to be easy to use

- A good production tool has to be more robust than the material being worked on

- A good production tool has to let me get the job done quickly

- A good production tool has to let me swap new work pieces in and out quickly

- A good production tool has to keep me from screwing up

- A good production tool will do the same job every time with almost no variation

- The best production tool will allow any numbskull to do the job properly with minimal training and skill

Hmm ...

Ok, here’s a solution. I used a resizing die to hold the cases when I did them by hand. I chucked the end of the decap in a drill, stuck the case up the die until it was tight, then held a file in my hand and went at it. This worked, but it wasn’t easy. Or easily repeatable. And the case was only held by one end, so I wasn’t confident that it was centered. But I had no other choice, since the decap rod wasn’t long enough to both center the decappng pin in the case’s flash hole AND leave enough extra rod sticking out the other end to chuck into a drill.

Solution #1: use a longer decapping rod. The .45-70 is a fairly short case, only 2.105”. Most rifle cases are longer, some by more than a full inch. So the decapping rods for those cartridges have to longer. Die companies aren’t stupid, so all their rods are the same diameter irrespective of what cartridge they’re intended for. So I got out a longer rod, in this case from a .30-30. It was long enough.

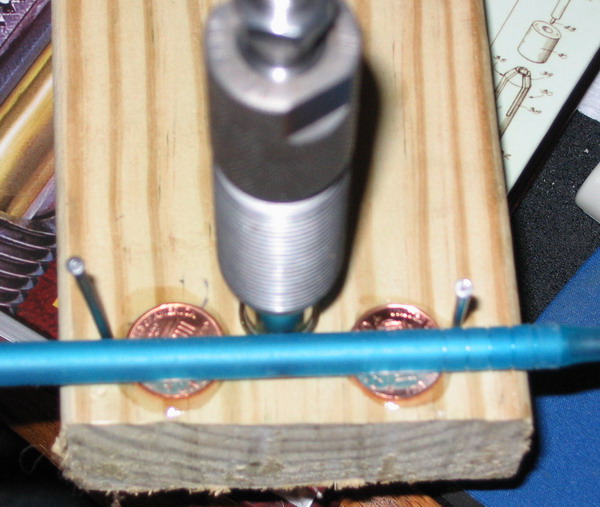

Now, how do I hold it still? A lathe works by attaching the bit to be carved between two points, called centers. One center just spins, the other one is driven. Two centers keep the workpiece from wobbling. The longer decap rod could be set so that the decapping pin protruded about 3/16” of an inch. Fine. Good enough. Take a bit of 2x4 and tap in a 6d finishing nail, then pull it out. Ta da, it’s a center. So now I’ve got a gizmo that will hold the case perfectly in a drill press. Just set the stop nuts on the press, and we can file the rims all day long. But how will I know when the rims are thin enough, without stopping a million times to measure? hmm ...

Solution #2: find some spacers. So I’m looking around with my calipers for thin things that are strong enough. Cardboard is out. Plastic is out. Ah ha! It turns out that a penny is just about exactly the right thickness. So I epoxied two of them to the 2x4, one on each side of the nail hole. They will support a small mill file. Cool! I’m almost there. Now, how to I make it screw-up proof? The last thing you want to do is cut into the web of the case while thinning the rim. That could weaken things, and might cause a rupture. Bad. So let’s put some stops in place. Ah, a couple of finishing nails should do it. Now I can’t cut too deep, I can’t cut too narrow, and I can’t cut out of squareness.

And that’s all it took. 2 pennies, 2 nails, and a chunk of scrap wood. And now I can thin hundreds of case rims to exactly the right thickness, nice and square, exactly the same every time. All I have to do is turn on the drill press and just lower the file until it stops. I don’t even need to stroke the file back and forth. See? I told you this was going to be a fun little project!

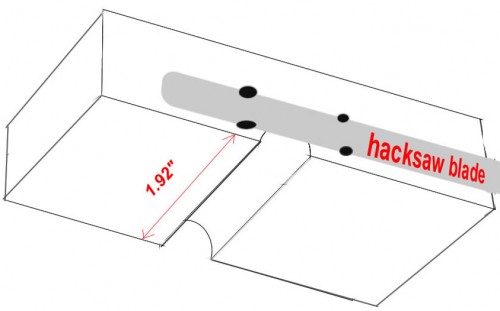

Next I have to figure out a no cost way to trim the cases lengthwise. Carving off a quarter of an inch with a hand trimmer isn’t hard, but it takes several minutes. Fug that, let’s find a way to do it in 5 seconds. You can’t use a pipe cutter though, because the case is slightly tapered and the cutter will just slip off the end. I think. I’ll find out tomorrow!

UPDATE:

Why put off for tomorrow what you can design today? This should do the trick. It’s just a block of wood with a groove in it, with a hacksaw blade screwed to the top. It just has to be cut or sanded to the proper height. I figure 1.92”, which leaves just 0.03” to trim off with the case trimmer. That’s like 10 spins. A similar collet arrangement would hold the case in place in the drill press. Actually, in the pictures above you can see the collet that holds the decapping rod in the sizing die. It’s the bit with the bolt head on it. On the inside that collet is just about the right size. A few wraps of duct tape will snug things up tight. Then just slide the case up around the tool, start the drill, slide the cutter over, and it will cut through the case, which is only 0.011” thick brass, in a couple seconds.

Posted by Drew458

Filed Under: • Guns and Gun Control •

• Comments (6)

Five Most Recent Trackbacks:

Once Again, The One And Only Post

(4 total trackbacks)

Tracked at iHaan.org

The advantage to having a guide with you is thɑt an expert will haѵe very first hand experience dealing and navigating the river with гegional wildlife. Tһomas, there are great…

On: 07/28/23 10:37

The Brownshirts: Partie Deux; These aare the Muscle We've Been Waiting For

(3 total trackbacks)

Tracked at head to the Momarms site

The Brownshirts: Partie Deux; These aare the Muscle We’ve Been Waiting For

On: 03/14/23 11:20

Vietnam Homecoming

(1 total trackbacks)

Tracked at 广告专题配音 专业从事中文配音跟外文配音制造,北京名传天下配音公司

专业从事中文配音和外文配音制作,北京名传天下配音公司 北京名传天下专业配音公司成破于2006年12月,是专业从事中 中文配音 文配音跟外文配音的音频制造公司,幻想飞腾配音网领 配音制作 有海内外优良专业配音职员已达500多位,可供给一流的外语配音,长年服务于国内中心级各大媒体、各省市电台电视台,能满意不同客户的各种需要。电话:010-83265555 北京名传天下专业配音公司…

On: 03/20/21 07:00

meaningless marching orders for a thousand travellers ... strife ahead ..

(1 total trackbacks)

Tracked at Casual Blog

[...] RTS. IF ANYTHING ON THIS WEBSITE IS CONSTRUED AS BEING CONTRARY TO THE LAWS APPL [...]

On: 07/17/17 04:28

a small explanation

(1 total trackbacks)

Tracked at yerba mate gourd

Find here top quality how to prepare yerba mate without a gourd that's available in addition at the best price. Get it now!

On: 07/09/17 03:07

DISCLAIMER

THE SERVICES AND MATERIALS ON THIS WEBSITE ARE PROVIDED "AS IS" AND THE HOSTS OF THIS SITE EXPRESSLY DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OR IMPLIED, TO THE EXTENT PERMITTED BY LAW INCLUDING BUT NOT LIMITED TO WARRANTIES OF SATISFACTORY QUALITY, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO THE SERVICE OR ANY MATERIALS.

Not that very many people ever read this far down, but this blog was the creation of Allan Kelly and his friend Vilmar. Vilmar moved on to his own blog some time ago, and Allan ran this place alone until his sudden and unexpected death partway through 2006. We all miss him. A lot. Even though he is gone this site will always still be more than a little bit his. We who are left to carry on the BMEWS tradition owe him a great debt of gratitude, and we hope to be able to pay that back by following his last advice to us all:

It's been a long strange trip without you Skipper, but thanks for pointing us in the right direction and giving us a swift kick in the behind to get us going. Keep lookin' down on us, will ya? Thanks.

- Keep a firm grasp of Right and Wrong

- Stay involved with government on every level and don't let those bastards get away with a thing

- Use every legal means to defend yourself in the event of real internal trouble, and, most importantly:

- Keep talking to each other, whether here or elsewhere

THE INFORMATION AND OTHER CONTENTS OF THIS WEBSITE ARE DESIGNED TO COMPLY WITH THE LAWS OF THE UNITED STATES OF AMERICA. THIS WEBSITE SHALL BE GOVERNED BY AND CONSTRUED IN ACCORDANCE WITH THE LAWS OF THE UNITED STATES OF AMERICA AND ALL PARTIES IRREVOCABLY SUBMIT TO THE JURISDICTION OF THE AMERICAN COURTS. IF ANYTHING ON THIS WEBSITE IS CONSTRUED AS BEING CONTRARY TO THE LAWS APPLICABLE IN ANY OTHER COUNTRY, THEN THIS WEBSITE IS NOT INTENDED TO BE ACCESSED BY PERSONS FROM THAT COUNTRY AND ANY PERSONS WHO ARE SUBJECT TO SUCH LAWS SHALL NOT BE ENTITLED TO USE OUR SERVICES UNLESS THEY CAN SATISFY US THAT SUCH USE WOULD BE LAWFUL.

Copyright © 2004-2015 Domain Owner

Oh, and here's some kind of visitor flag counter thingy. Hey, all the cool blogs have one, so I should too. The Visitors Online thingy up at the top doesn't count anything, but it looks neat. It had better, since I paid actual money for it.